When specifying radiator guards, the conversation often focuses on materials, safety features, and access. However, integrating TRVs (Thermostatic Radiator Valves) into the guard design is a critical element that directly impacts control and safety.

From maintaining comfortable room temperatures to protecting against tampering in secure environments, TRV specification must be carefully aligned with the radiator guard itself. If it's overlooked, the result can be poor energy performance, difficult maintenance access, or even safety risks.

In this blog, we explore the key TRV options available from Contour and explain how integrating the right solution at the manufacturing stage can make all the difference.

Why TRVs Matter

TRVs are used to regulate the heat output of a radiator by responding to the temperature in the room. In healthcare, education or secure environments, correct TRV placement ensures:

- Safe and consistent room temperatures

- Energy-efficient operation

- Reduced maintenance callouts

- Controlled user access to heating controls

When a TRV is enclosed by a radiator guard however, it must still be accessible, protected from tampering, and appropriately ventilated to work effectively.

That’s where the radiator guard design and manufacturing process come in.

TRV Options Available from Contour

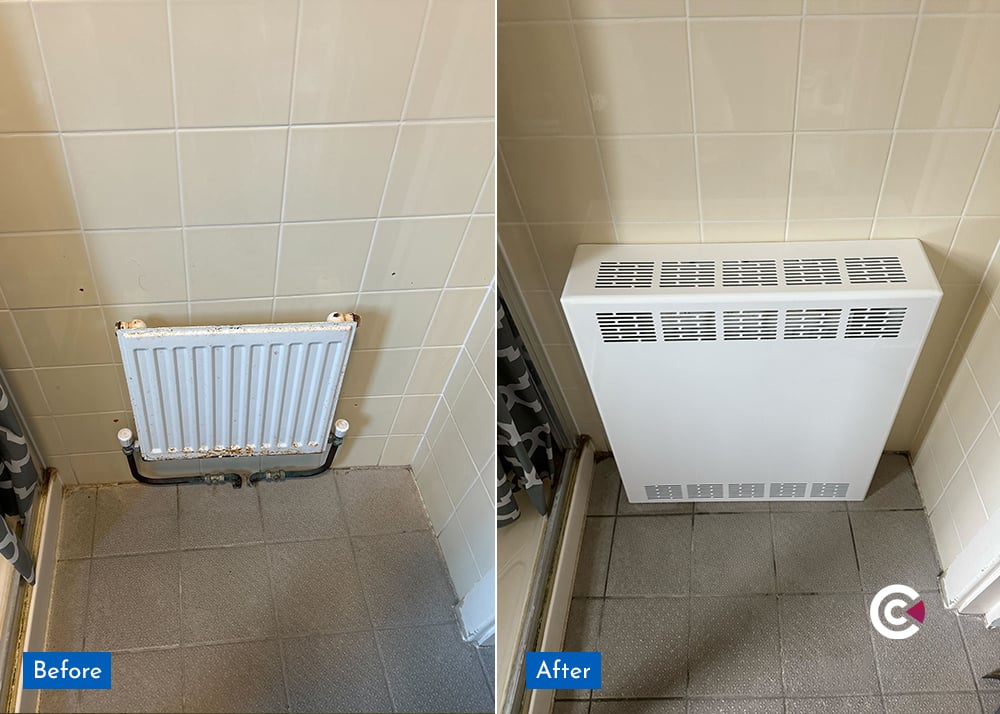

Contour offers a variety of TRV kits and integration options, depending on the environment and level of risk. Every DeepClean , DeepClean Extra and Covora radiator guard is made to order, which means TRV cut-outs are built in during manufacture - no site cutting required.

Here are the main TRV configurations available:

1. External TRV Kit

Ideal for low-risk settings such as education or general healthcare environments. The TRV is mounted externally on the outside of the guard. This allows staff or users to manually adjust the temperature without accessing the inside of the casing, which is ideal for environments where control needs to be accessible and tamper resistance isn’t a top priority.

Although the TRV sits outside the guard the casing is manufactured with a pre-cut opening to accommodate the valve body. This removes the need for on-site alterations and ensures a neat, secure fit that maintains the integrity of the powder-coated finish.

To reduce the risk of tampering, a locking pin mechanism is available to prevent unauthorised adjustment of the valve, which is particularly useful in educational or mental health settings.

- External valve allows for easy access to temperature control

- Locking pin option helps prevent tampering

- Factory-cut TRV opening ensures a clean installation

2. Internal TRV Kit

This is the preferred option for moderate-risk areas, where tampering is more likely, but staff still require access.

- TRV is fitted inside the guard

- Controlled by opening the drop-down door

- TRV is protected and concealed but still easy to reach for maintenance

3. Internal TRV with Remote Sensor

This configuration is specifically suited to radiators with Top Bottom Opposite End (TBOE) connections, where the thermostatic control head is positioned at the top of the radiator. In these cases, heat naturally rises and may cause the TRV to shut off too early unless the sensor is located elsewhere.

That’s where the remote sensor comes in.

In this setup, the TRV remains inside the guard, but the sensor can be installed lower down, either mounted on the bottom inlet grille or externally on the wall adjacent to the guard. This positioning ensures a more accurate reading of ambient room temperature, helping maintain consistent heat output and improving energy efficiency.

By adjusting for TBOE setups, this option supports environments where precise temperature control is important but without needing to place the TRV externally.

4. Anti-ligature External TRV Kit

Developed for mental health and secure settings, this kit includes:

- External TRV

- Full back-to-wall shroud to prevent tampering from behind

- Specially designed to reduce ligature risk

This kit provides controlled external access while ensuring compliance with safety protocols in high-risk environments.

TRVs and Made-to-Measure Manufacturing

Unlike off-the-shelf guards, Contour’s radiator covers are bespoke. That means TRV integration is planned from the outset ensuring:

- Correct clearance for access

- Accurate pipework and skirting cut-outs

- No need for drilling or cutting on-site

- A cleaner finish with reduced installation time

In environments like hospitals, schools or secure units, this matters more than ever. Guards must arrive ready to install, fitted to the walls, floors, and pipework layout exactly as required.

TRV Integration and Access Panels

Contour’s DeepClean and DeepClean Extra guards are designed for ease of access, which directly supports TRV maintenance and adjustment.

Both models feature a drop-down door, which lowers safely to the floor for authorised users to:

- Access the TRV

- Adjust settings or check operation

- Bleed the radiator

- Clean around the valve area

This not only reduces the time needed for estates callouts but also eliminates the need to remove the whole cover just to reach a valve.

Need Help Matching the Right TRV Solution to Your Radiator Guard Specification?

Whether you’re working in a mental health setting, hospital, or school, Contour’s team can help you choose a configuration that balances performance, safety and accessibility.

📧 sales@contourheating.co.uk

📞 01952 290 498

🗓️ Or book a site survey to walk through your site requirements with our technical team.

-1.png)

/anti-ligature%20vent%20grilles.jpg)