Section 136 Suites are designed to provide a ‘place of safety’ whilst individuals are being assessed under Section 136 of the Mental Health Act.

Due to the vulnerability of the individuals using these spaces, it’s crucial that furniture, fixtures, fittings and appliances are optimised to maintain safety standards, and to provide a comfortable environment.

Are you involved in the design or specification of a 136 suite? This blog will run through the design considerations that you’ll need to ensure a safe environment for those using a Section 136 facility.

We’ll be discussing:

- Anti-ligature features

- Strength and durability

- Hygiene considerations

Read on to find out more…

Anti-Ligature Solutions For A 136 Suite

It’s important to understand the state of mind that users are likely to be in when they’re detained and placed in a Section 136 suite.

Aggression, fear and confusion will most likely be driving the behaviours of these individuals, which is why anti-ligature products are a key consideration.

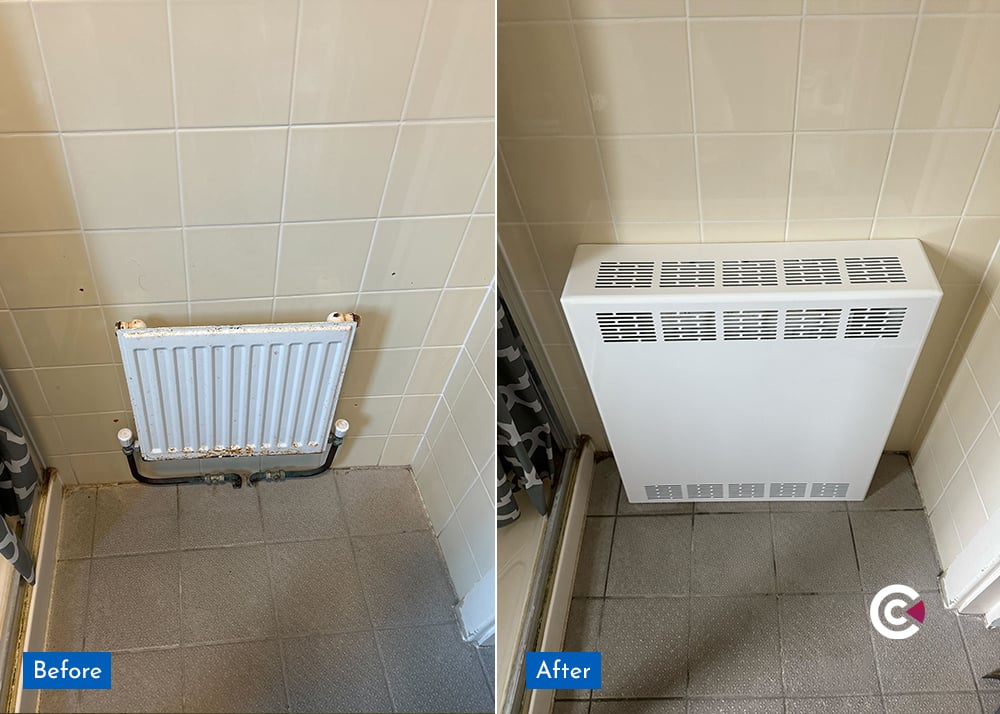

Radiators and air conditioning (AC) guards within 136 suites should be designed to be extremely difficult for an individual to use the appliance as a ligature risk.

It’s easy to assume that ligature risks take place above head-height. Whilst this is true, studies show around 50% of hanging suicides are not fully suspended—ligature points below head level are commonly used.

These points may come from less obvious places, like a radiator or an AC unit.

We recommend there to be no gaps or joints within heating solutions and for grilles to be IP3X compliant to avoid anything being tied between them.

Having bull-nosed, rounded corners and no sharp edges need to also be considered to avoid harm to individuals and other service users.

Built To Withstand Vandalism

Vandalism is something that is a common occurrence of prisoners and this is no different in 136 suites. These acts of vandalism can lead to individuals using furniture to create ‘weak points’ in other parts of the suite such as doors, windows sanitary wear. Therefore, it's important to search for a radiator guard or AC unit that’s strong and robust to withstand such damage.

Zintec steel material is a strong solution to protect heating from vandalism, damage, and corrosion.

Heating Efficiency In Section 136 Suites

Various traditional radiators operate on a pipe coil system, which has several downsides from a design and efficiency perspective.

Often obtrusive and unattractive, pipe coil systems use far more water due to its wide diameter pipe, in comparison to an anti-ligature radiator-which operates on a much smaller section of pipework, taking up less space.

Anti-ligature radiators can work to reduce the need for radiators to operate for lengthy periods and therefore, can heat up quicker.

Optimise Hygiene Levels

As we all have increasingly become more aware of the hygiene practices we follow, we can understand the importance of cleanliness in any given environment.

Due to 136 suites having high patient turnover with individuals only staying for short periods, suites need to be regularly cleaned to reduce the spread of infection.

Therefore, radiators and air conditioning guards must have easy access for cleaning and maintenance to ensure hygiene is maintained for each service user.

Conclusion

Contour’s anti-ligature solutions are designed with IP3X grilles to ensure ligature risks are reduced.

With bull-nosed corners, rounded edges, no sharp points, and being made with Zintec steel the radiators and AC units are solid and robust to avoid harm to all service users.

With Contour, hygiene is carried-out with easy access for cleaning and maintenance. Covers can drop-down effortlessly. To drive hygiene further, BioCote® anti-microbial protection is introduced at the manufacturing stage.

This unique, patented additive provides an effective, safe and long-lasting solution to combatting a wide range of dangerous bacteria, including MRSA and E.coli.

About Us

Contour produces a range of innovative, safe surface temperature systems for healthcare, education, mental health, commercial and secure sectors, working in close partnership and collaborating with architects, M&E engineers, NHS Trusts, local authorities and contractors to deliver outstanding safe heating solutions.

Contour is the exclusive partner of BioCote® anti-microbial technology for LST and anti-ligature radiators. BioCote® additives reduce bacteria by up to 99.9%. Contour combines an extensive range of colour-paints is with BioCote® for a durable, high-quality finish.

Contour’s heating solutions offer secure, single-person quick access to radiator guard interiors for regular deep cleaning and maintenance. Each year, Contour save the NHS millions of pounds in cleaning costs, therefore delivering cleaner, safer environments. Contour is redefining the marketplace and therefore many regards us as a design and innovation leader within the industry.

Contour has a quality-first philosophy. Our customer-focused team possess a ‘can-do’ attitude, they take pride in developing solutions for your heating requirements.

Contact us at:

The Mansions, 43 Broadway Shifnal

Shropshire TF11 8BB United Kingdom

+44 1952 290 498

Twitter: @Contour_Heating

LinkedIn: Contour Heating Products Ltd

-1.png)

/anti-ligature%20vent%20grilles.jpg)