In safety-critical environments, spec sheets and technical data matter; but so does what happens when a product meets the real world, especially in unpredictable, high-risk settings.

That’s why we go beyond the datasheet when it comes to Contour’s anti-ligature window protectors.

Why Standard Testing Isn’t Enough

Traditional safety tests might tell you how strong a material is, or how much pressure a component can take in controlled conditions. On a mental health ward, in a children’s home, or in secure accommodation however, those conditions don’t exist.

You need to know:

- What happens when the product is tampered with using everyday objects?

- What failsafe exists if someone exerts major force - not once, but repeatedly?

- What if someone’s intent is to destroy the protector entirely?

This kind of real-world risk can’t always be modelled in a lab, so we created our own rigorous in-house testing programme.

What We Tested and Why

Following feedback from professionals in the field, we conducted a series of impact and tamper tests that simulated real-life behaviours seen in high-risk settings.

We focused on three core areas:

- Tamper-resistance:

Our Secure compression cam locks were subjected to attempts at forced entry using commonly available ward items. This helped us identify exactly how they hold up in day-to-day scenarios and where reinforcements could be made. - Structural strength:

We applied repeated physical force at vulnerable points, including vision panels, grille cut-outs, and fixings. Rather than applying a one-off static load, we aimed to recreate ongoing aggression, as would happen in a real incident. - Destruction testing:

In the harshest of trials, we tested to destruction. What happens when someone is determined to break through the protector? We analysed how and where failures occurred to ensure no single weakness compromises overall safety.

How This Informed Product Development

Every test, every breakage, and every failure point told us something important.

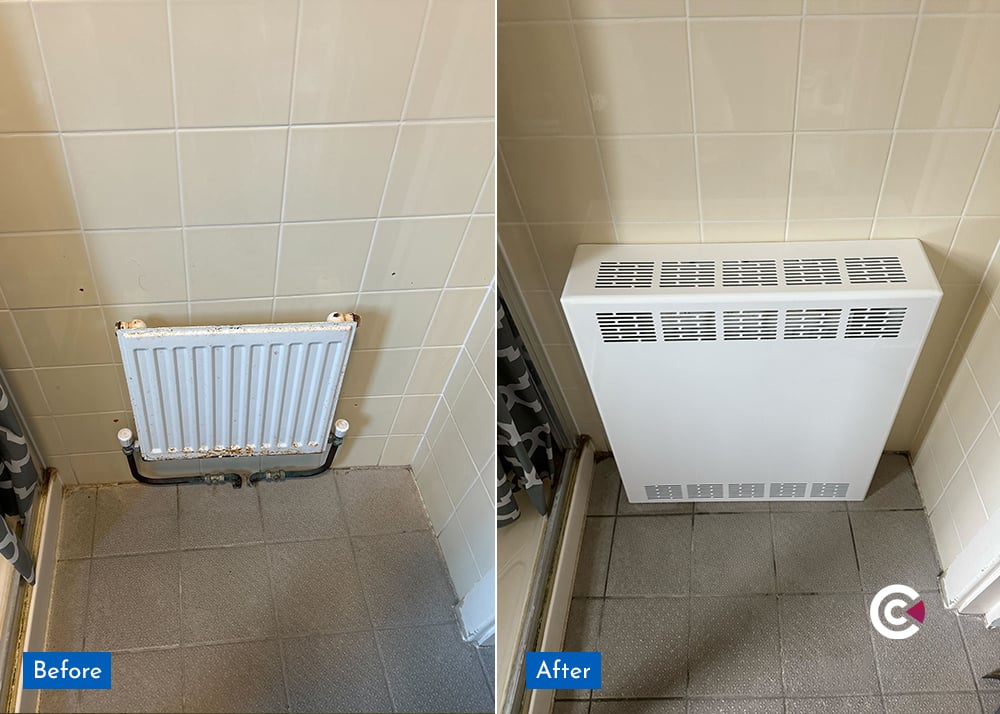

Informed by the results, we’ve enhanced key aspects of the design and built confidence in areas already performing well. The optional features such as the ventilation grille and anti-ligature privacy blind were also reviewed to ensure they offered genuine robustness without compromising safety or practicality.

The outcome?

A more refined, more confident product, shaped not just by compliance standards, but by the realities our customers face every day.

Why This Matters for Your Setting

When you choose an anti-ligature window protector, you're not just choosing a spec. You're choosing:

- Peace of mind that the product won’t fail under pressure

- Confidence that it’s been developed with real-world behaviours in mind

- A safety-first solution for the people who matter most

From secure healthcare to residential care, every setting deserves that level of reassurance.

Need Assurance Beyond the Spec Sheet?

Explore how Contour’s anti-ligature window protectors are engineered and tested to meet real-world challenges. Let’s talk about how they can work in your setting.

🔗 View the window protector range.

📞 Call us on 01952 290 498

📩 Email us at sales@contourheating.co.uk

-1.png)

/anti-ligature%20vent%20grilles.jpg)