One of the questions that we are often asked by potential customers is how much do metal radiator covers cost? This can be a very complex question to answer but we shall try to explain what goes into the price of a metal radiator cover below.

Buying metal radiator covers can be similar to buying a car or any other purchase where there are various options available on top of the basic package. Many features in a higher cost model are simply not available on the cheap deal, so you are never really comparing like with like.

When you think that the average person will replace their vehicle every 3 to 4 years it may seem strange that they choose so many upgrades which will significantly increase the cost of the car they are buying.

However, we are sophisticated buyers in this country and we understand the value of getting the right product to suit our needs and the way that we intend to use the car. You understand the difference between a cheap price and good value.

More Than Just a Box on a Wall

This is similar to metal radiator covers too. At first thought, it would be easy to think that they are simply metal boxes that are fitted over a radiator to protect vulnerable service users from injuring themselves on hot surfaces.

The true answer is very different. There are many different environments in which metal radiator covers are used. It is critical that the design must be fit for purpose in these different types of buildings with many different types of service user. For example, a radiator cover fitted in a high-security prison will have completely different design requirements and options than a radiator guard used in a nursery school.

Find out where you can use metal radiator covers

So let’s look at the different options available and factors which can so dramatically affect the cost of your metal radiator cover.

1. The Size Of The Radiator Cover

It may seem obvious but the radiator cover is custom designed to fit over your existing radiator. This can be anything from a small toilet with a single panel 400mm wide radiator, through to a long corridor with multiple radiators, which requires continuous bespoke radiator casings that can be several metres long.

The radiator casing height can also have an impact on price. Sufficient space needs to be allowed above and below the radiator to ensure good circulation and minimal heat loss. As casings basically converters a radiator into a natural convector unit. One thing that often affects the height of the casing is the height of the existing radiator above the floor.

Finally, the depth affects price too. Deeper radiators require deeper casings, and old-fashioned column radiators can often be 200 to 250 mm deep which will lead to casings around 300mm in depth.

These factors can make quite a difference to the way that radiator covers are manufactured. All casings are from standard metal sheets. As they are programmed the layout of the parts is optimised to increase sheet utilisation, which reduces waste and aims to keep costs down. Sometimes, for larger radiator covers, special sheet sizes are needed which can be expensive to purchase in small quantities.

2. Application

The environments in which the metal radiator covers will be installed can have quite an impact on the construction of the radiator cover itself. Low traffic, low-risk areas such as a nursery school classroom would be sufficient with a lightweight cover with no additional options to provide a safe solution for the building occupants.

When you start to fit products into more challenging environments such as mental health units, custodial facilities, or high traffic areas such as hospital corridors, then you need to consider the strength of the radiator, preventing unauthorised access, or maybe providing anti-ligature grilles to ensure patient safety. These options may not be available in off-the-shelf, mass-produced products.

Many radiator covers are manufactured from thin, lightweight 1.2mm steel, mainly to reduce cost and save weight. These lightweight products will not withstand the rigours of demanding environments. For these type of projects, it is best practice to use a thicker gauge of steel, such as 1.5mm or 2mm thick material.

You may wish to add additional reinforcement for areas used by extremely challenging service users. Specialist radiator cover companies, such as Contour will be able to provide highly bespoke products, tailored to your precise needs, to ensure patient safety and maximum product life.

3. Easy Of Cleaning & Low Maintenance Costs

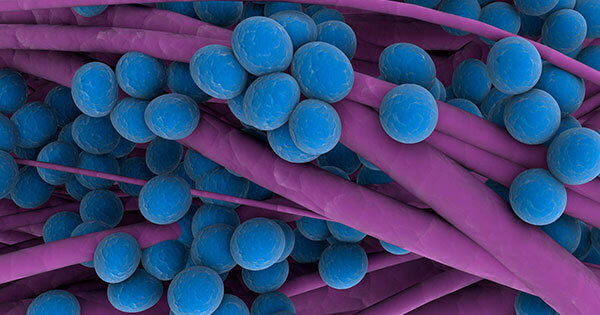

The increased awareness of antibiotic-resistant bacteria and the dangers they pose to patient safety, has driven many changes in Health Care and wider environment. Ensuring that these facilities are hygienic is now a key priority for building managers, and where possible products should be designed with hygiene and ease of cleaning in mind to help provide cleaner, germ-free environments.

At Contour we have been obsessed with ensuring our designs are easy and quick to clean. This provides safer patient environments and keep's the lifetime cost of cleaning and maintenance as low as possible.

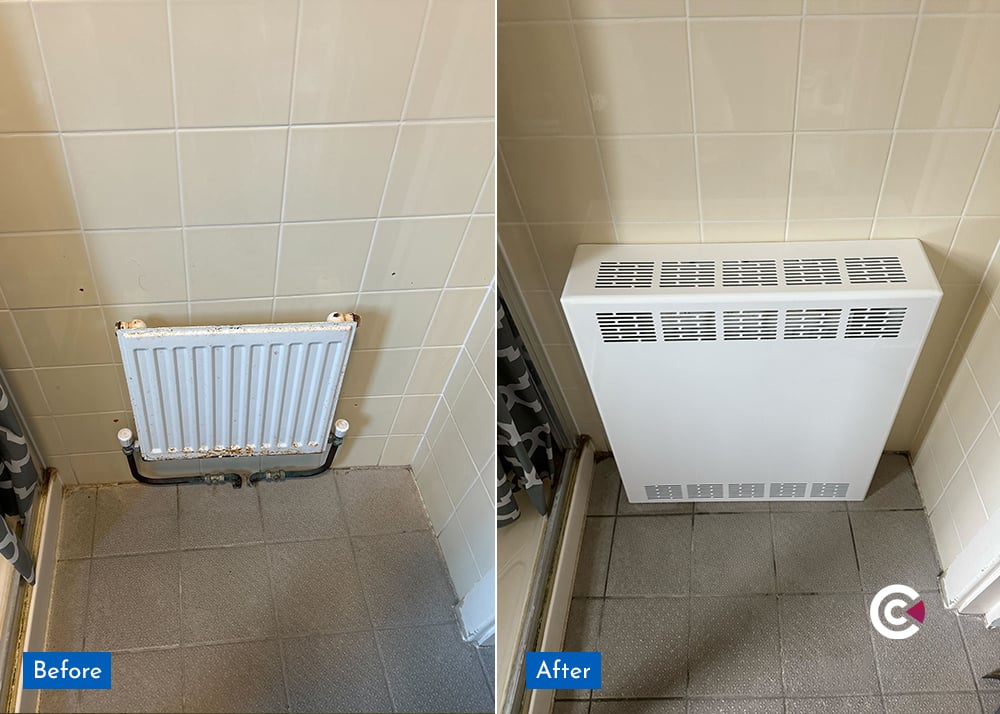

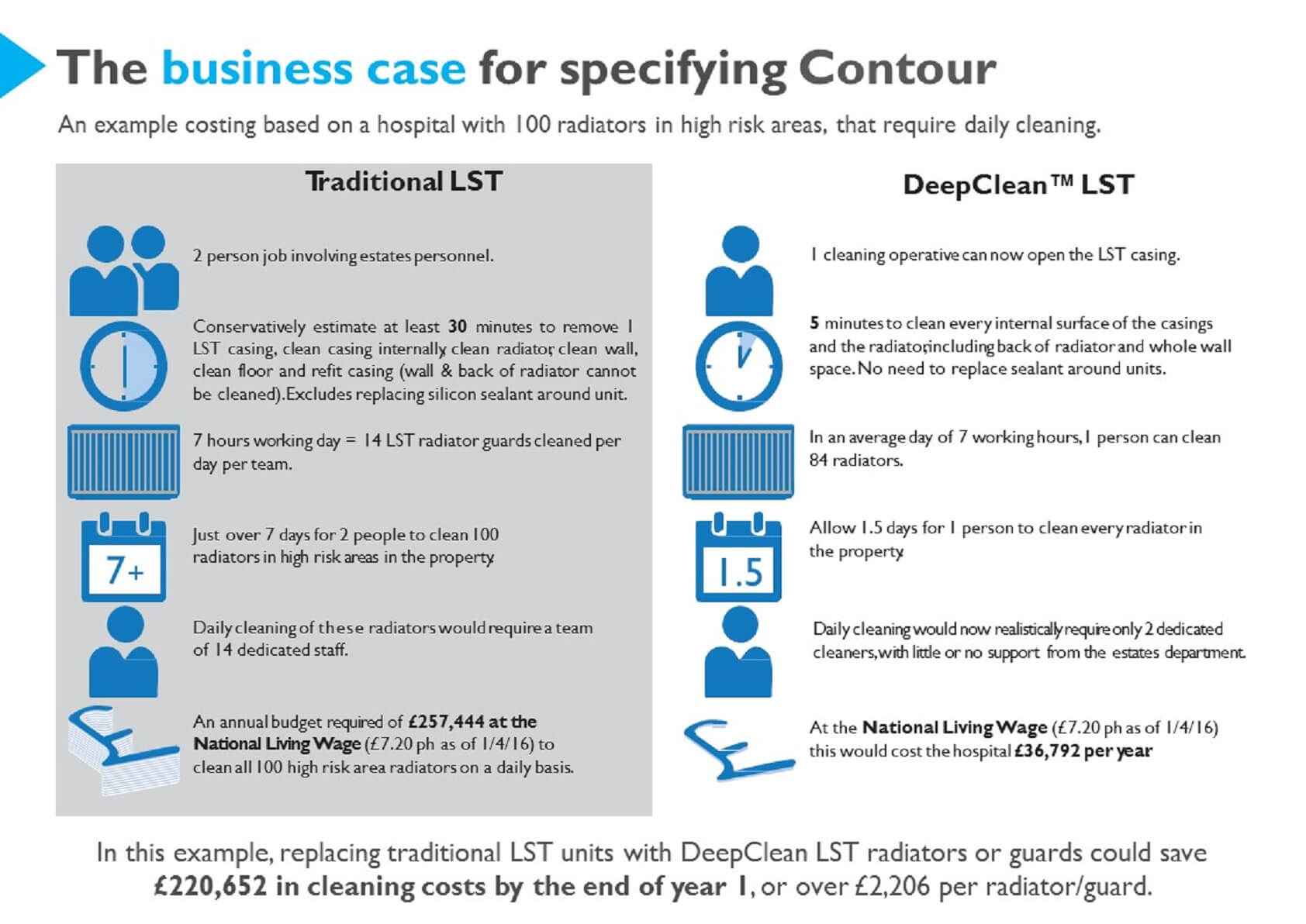

Compare the costs of cleaning Contour radiator covers with old-fashioned fixed units which need specialist personnel to remove the whole cover from the wall to enable the cleaning team to access the radiator cover interior for cleaning.

Quick and easy unaided access is critical to all Healthcare requirements. The national specifications for cleanliness in the NHS require radiators to be cleaned weekly. Installing old fashioned fixed units hinders this process as Estates personnel will need to be deployed to remove radiator covers prior to the clean, and then afterwards to refit them. Clearly, any saving made in the capital purchase of cheap, fixed radiator covers will quickly be outweighed by the weekly cost of sending a team from Estates to remove and refit the radiator covers that need to be cleaned.

Unfortunately, what usually happens, is that the exterior of the casing is just wiped over, leaving the interior untouched. This poses a serious health risk, as MRSA can live up to 7 months in the dust on internal surfaces, which can then be recirculated into the environment as air passes through the radiator cover when in use.

Well designed radiator covers provide quick and easy access for cleaning, without the need to Estates personnel to be involved. These covers do cost more than cheap fixed units as they have more components and take longer to manufacture. But, as illustrated above, the payback is incredibly short, and the in-service costs of an old-fashioned fixed radiator cover soon escalate, or worse, precipitate an outbreak of MRSA with potentially fatal consequences.

4. Anti-microbial Finish

The use of anti-microbial coatings on metal radiator covers has become widespread in recent years, as healthcare providers demand cleaner environments for their service users. Whilst a welcome advance, there are many misconceptions about the coatings available, and care must be taken to ensure that a high-quality solution is used to prevent unwanted failure or underperformance of the coating.

When specifying or buying products with anti-microbial properties, it is best practice to ask for the following information from the supplier to ensure that you are getting a product that is safe and fit for purpose in your environment.

- What is the anti-microbial agent? - You need to ensure that a broad spectrum antimicrobial additive is used. preferably the agent is based on Silver ions, as it is proven to protect products from colonisation and therefore the negative effects of microbes like bacteria and mould, making products more hygienic, longer lasting and safer to use.

- How does the Technology work? - By introducing silver ion technology during the manufacturing process a product becomes inhospitable to microbes that may contaminate them. The silver ions within the product are attracted to the contaminating microbes and once in contact works against them in multiple different ways at the same time – silver has what is called a multi-modal action. This combination of mechanisms irreversibly damages microbes, prevents reproduction and repair and disrupts functions essential to life, ultimately causing them to die. Agents other than Silver may not have the same proven action.

- How Often Is the Antimicrobial Solution Tested and How Effective is It? - Reputable antimicrobial solutions providers contractually oblige their customers to regularly have their products quality control checked for antimicrobial efficacy. Whilst current legislation only requires the manufacturers have a single dataset that supports an antimicrobial claim each responsible manufacturers have their own rigorous, independent testing schedule that will require the testing of multiple products samples a year. Be sure to check the level of antimicrobial performance. No minimum standards exist for antimicrobial performance, so be sure to ask for independent evidence of the efficacy the antimicrobial technology used.

- What Microbes is the Antimicrobial solution effective against? - Best in class antimicrobial solutions have been proven effective against a wide range of microbes including bacteria, mould and fungi - even multi-drug resistant bacteria and the H1N1 virus cannot survive exposure to their industry standard-setting additives. A test protocol like ISO 22196 uses two specific bacteria, (MRSA and E.coli) for the purpose of the test these two bacteria are considered representative of all bacteria. Performance against these two bacteria is considered proof of performance against all. This handy guide provides the full list of microbes that the BioCote® additive used on Contour products is effective against.

- How Well Does it Work? - Ensure that the antimicrobial protected products you are choosing have not only been proven to work in the lab, they have also demonstrated a real-life benefit.

Ask for studies in environments such as Hospitals, Care Homes, Schools and Food Production facilities to prove the positive impact and benefit of antimicrobial protected products on the environments they are used within and the people that use them. - How Long Does It Take To Work? - Whilst silver based antimicrobial technology is not instant, like cleaning, it has other advantages. For example it works continuously for the expected lifetime of the product, unlike cleaning where the effect is very short term. Check laboratory tests to ensure rapid action such as tests that demonstrate reductions of up to 86% in just 15 minutes, and over 99% in 2 hours.

5. Anti-ligature Features

The awareness of the risk from ligature points in mental health and custodial facilities has heightened in recent years, following investigations into tragic suicide attempts. The Ministry of Justice has issued guidelines relating to the design of grilles when used in high-risk areas, which calls for circular holes no more than 2mm in diameter at a 4mm triangulated pitch. This design will prevent ligatures as small as shoelaces being able to be attached to these grilles.

This MOJ guidance has been widely adopted by the NHS in England, Scotland and Wales, and is also required by all of the major Private Mental Health providers. Independent testing, by a UCAS accredited test house, of the grilles to the IP3X (BS EN 60529) standard will verify that no object greater than 2mm in width can penetrate this grille, and this standard should be required when specifying metal radiator covers for high-risk areas.

Another concern that has been highlighted recently is gaps along uneven walls when radiator covers are fitted. Filling these gaps with anti-pick mastic is impractical when the metal radiator cover design has a drop down door design for cleaning. To overcome this problem, some specialist radiator cover manufacturers have developed new designs which provide a fixed back rail, which can be sealed, whilst still facilitating ease of access for cleaning.

A final consideration for anti-ligature protection is addressing the risk of exposed TRV's being used as an anchor point. The use of heavy duty, milled aluminium shrouds is commonly accepted as being best practice, as these make attaching the ligature far more difficult. Some cheaper options such as presses metal shrouds have appeared on the market, but there have bee reports of these being easily damaged as they are manufactured from a thin metal sheet and simply spot welded into position.

6. Installation Costs

It is still surprising how many radiator covers have been designed and manufactured by people who have never actually installed one. This is normally evident as soon as the packaging has been opened and you see one of your engineers scratching their head, looking puzzled and holding a part that they have no idea what to do with. Well designed metal radiator covers tend to have been designed by specialist companies who actually install them too.

They know all the challenges that you can face, which is why their installation experts have had a hand in designing the cover to make it as quick and easy to install as possible. Think about it, they want the cover to be easy for them to install too.

Well designed covers don't arrive in kit form, requiring time-consuming assembly, they are supplied in one piece and are complete with factory skirting and pipework cutouts to eliminate site cutting, which is noisy, difficult and can easily lead to damage to the casing, requiring expensive repairs.

Up front savings on the cost of purchasing the cheap, poorly designed radiator covers are soon eaten up by the extra time it takes to install them if they have not been designed with you, the installer in mind.

7. Safety Designed In

It is still a surprise to see metal radiator guards on the market with square corners and sharp edges. Often the reason why cheap radiator covers are the price they are is that they have been manufactured in a way that makes them quick and inexpensive to produce, rather than safe for the end users in the environment that they will end up in.

The risks to elderly service users or young children from falling, head first into a sharp corner do not need to be graphically explained. This is why paying the extra for products that require additional fabrication and welding to provide safe corners and edges is a small price to pay for long term patient safety, and eliminating the risk of being sued in the event of a nasty accident.

Conclusion

This is why, when we are asked how much do metal radiator covers cost, we know it can be a long conversation, and if you have got to the end of this article, well done! It is often said that you get what you pay for. This is just as true with metal radiator covers as any other products. Sure - you can buy a low cost, off the shelf option for around £200 each, but ask yourself is it fit for purpose in your building? How easy is it to clean? How quick and easy is it for you to install? Who will survey it to ensure a perfect fit? How long will it last? How effective is the anti-microbial coating? Has it been designed specifically for your application or is it a one size fits all type of product?

If you are unsure about any of these questions, there is a fair chance that the long-term costs of your metal radiator cover could way exceed the ticket price on the capital purchase. Which is why Contour Radiator Guards may not be the cheapest product you consider, and if the price is your only consideration, it is probably not worth contacting us.

But in terms of life expectancy, safety, cleanliness, cost of maintaining, cleaning providing a proven antimicrobial solution, Contour are confident that we provide the best value for money on the market. Contour Metal Radiator Covers are products that we are proud of and passionate about, and it shows in the quality of product design and service that you will receive from us.

About Us

Contour produces a range of innovative, safe surface temperature systems for healthcare, education, mental health, commercial and secure sectors, working in close partnership and collaborating with architects, M&E engineers, NHS Trusts, local authorities, design consultants and contractors to deliver outstanding safe heating solutions.

Contour is the exclusive partner of BioCote® anti-microbial technology for LST and anti-ligature radiators. BioCote® additives reduce bacteria by up to 99.9%. Contour combines an extensive range of colour-paints is with BioCote® for a durable, high-quality finish.

Contour’s heating solutions offer secure, single-person quick access to radiator guard interiors for regular deep cleaning and maintenance. Each year, Contour save the NHS millions of pounds in cleaning costs, therefore delivering.

-1.png)

/anti-ligature%20vent%20grilles.jpg)