When designing highly secure facilities, such as mental health institutions, correctional facilities, schools, or any environment with potential ligature risks, a critical aspect of the design process revolves around the careful selection and installation of Anti-Ligature Radiator Covers. These specialised products play an important role in mitigating ligature risks and enhancing safety within the facility. Below, we’ll look into the process of specification for an Anti-Ligature Radiator Cover.

First Stage: Free Site Survey to Identify the Need

It starts with a comprehensive Site Survey, a vital first step in ensuring the proper installation of Anti-Ligature Radiator Covers. Experienced surveyors with technical expertise in Radiator Cover installation would assess the site. They identify special requirements, such as cut-outs, corner-fitted units, and potential clashes with other fixtures and fittings.

During this phase, several key tasks take place:

Location and Purpose Assessment

The process starts by determining the specific location and purpose for the Anti-Ligature Radiator Cover. This initial assessment identifies areas where ligature risks exist.

Conducting a Risk Assessment

To mitigate potential risks, a thorough risk assessment is conducted. This assessment identifies any existing fixtures or elements that could pose a ligature risk, ensuring that the Radiator Cover effectively addresses these concerns.

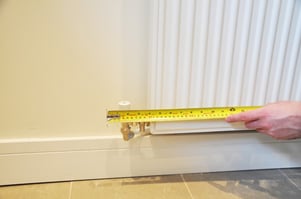

Establishing Accurate Measurements

The next step is to establish the detailed specifications for the Anti-Ligature Radiator Cover. This includes determining:

- Size and dimensions to precisely fit the Radiator.

- Material specifications, ensuring it is Anti-Ligature, durable, and easy to clean.

- Finish and colour options to suit the environment.

- Ventilation requirements to guarantee proper heat distribution.

- Compliance with relevant safety standards and regulations, ensuring the highest level of safety.

Our surveyors would then work in close collaboration with you, offering innovative and cost-effective design suggestions that reduce installation time and lower overall costs. Any necessary modifications will be integrated into the manufacturing process, ensuring a streamlined and efficient installation.

Second Stage: Receive Quotes and Lead Time Estimation

After defining your requirements, the next step is to wait for the quotes based on these specifications. The lead time for Contour’s Made-to-Order Radiator Covers is approximately 10-14 days. All products from Contour, including radiator covers are designed and manufactured in the UK from mild steel, ensuring exceptional durability.

All Contour products come with comprehensive warranties, ensuring your peace of mind. This includes an impressive 2 year Warranty on all Radiators and Valves and a reassuring 2 years Warranty on Radiator Covers.

Third Stage: Delivery and Installation

Your LST Radiator range will then be coordinated for delivery and professional installation through split deliveries.

Radiators and Valves are delivered first, while casings are delivered once the heating system is installed, tested, and commissioned. This approach minimises storage issues and the risk of On-Site damage.

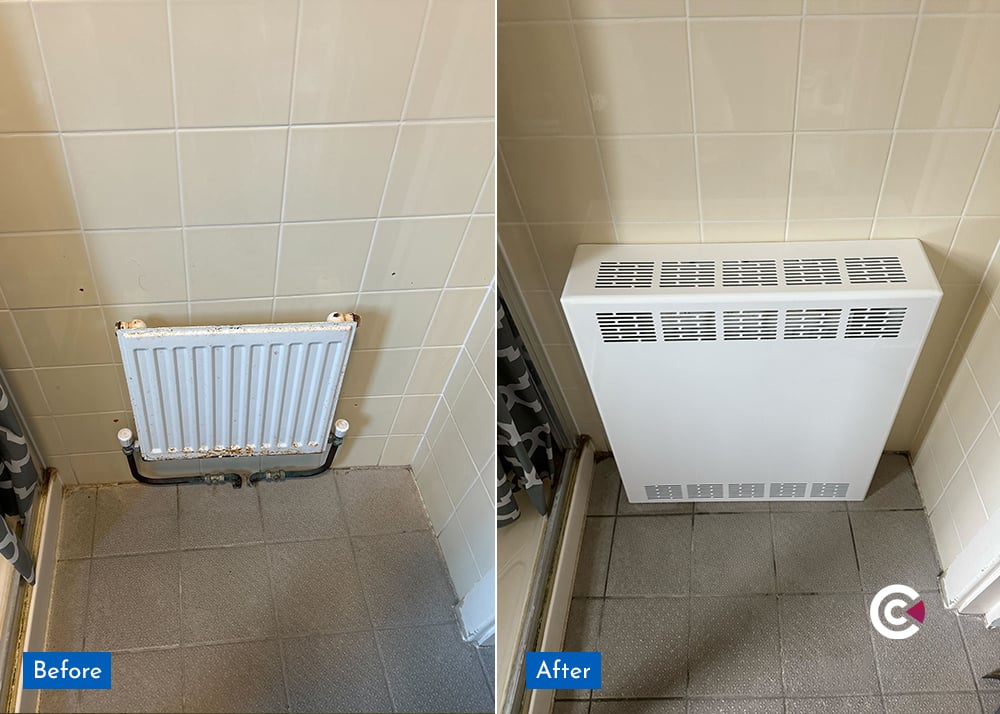

Final Stage: Installation Service

The last stage involves the actual installation of the Anti-Ligature Radiators and Covers.

We offer a 'supply-and-fit' service to most LST and Anti-Ligature Guard Products, with project management teams overseeing the entire process to minimise disruption to your facility's operations. The skilled fitting teams will carry out installations professionally and efficiently, all at competitive rates.

You can trust us to deliver versatile heating solutions tailored to your facility. Whether it's a renovation project or a new construction project, whether you require the installation of a single radiator cover or multiple guards throughout your facility, Contour is committed to improving safety and reducing ligature risks effectively.

Specialist Safe Heating For Mental Health Facilities: DeepClean Extra

Looking to specify an Anti-Ligature Radiator for your facility?

The DeepClean Extra Range is a specialist heating solution designed in response to real-life challenges encountered in the mental healthcare sector. It ensures the products remain attuned to the evolving and unique needs of the environment, mitigating potential safety risks.

Built with robust and durable 1.5-2mm Zintec Steel or Magnellis Steel for wet rooms, this range is engineered to withstand demanding environments with ease. The Anti-Ligature design incorporates IP3X-Rated Grilles tested by a UKAS-accredited laboratory and certified to protect against the ingress of objects greater than 2.5mm in diameter. Anti-Ligature TRV Kits are also available to allow service users to take control of their heating to increase comfort levels.

Get in Touch Today and Book a Free Consultation with one of our heating experts to discuss Anti-Ligature heating solutions for your facilities.

-1.png)

/anti-ligature%20vent%20grilles.jpg)