Designing heating for high-risk environments is never just about comfort. In prisons and safer cells, as well as Young Offender Institutions (YOI), police custody suites, 136 mental health assessment suites, immigration detention centres and Pupil Referral Units (PRU), heating must balance safety, security, hygiene and durability, while remaining practical to install and maintain.

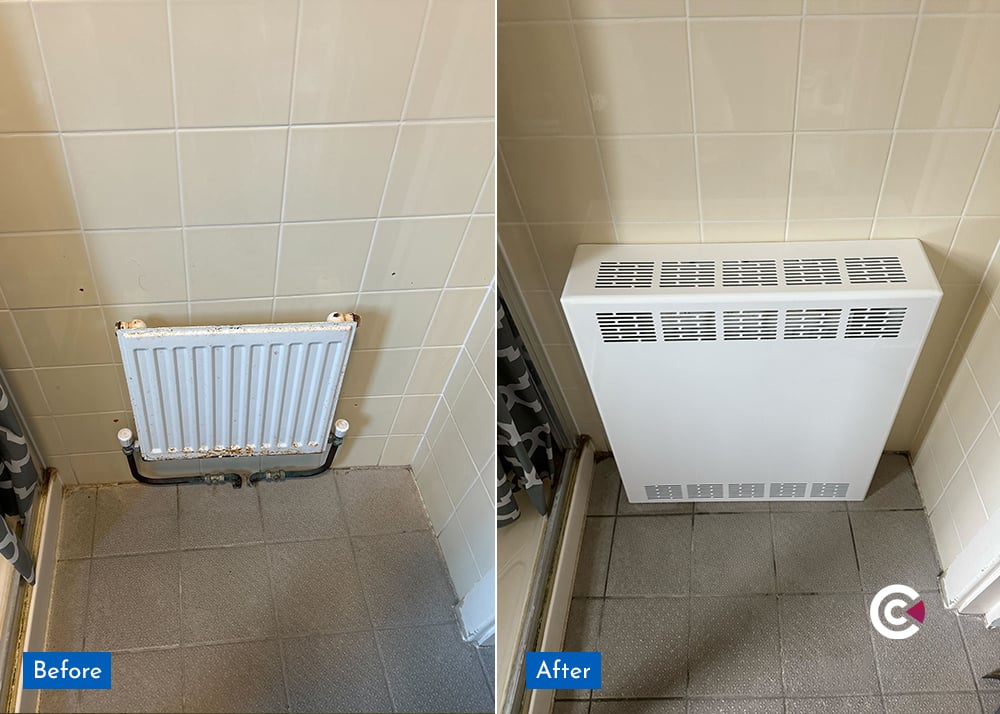

From recent custodial projects, several clear lessons emerge. They show why an anti-ligature radiator that is MoJ-approved for safer cells, such as DeepClean Extra+, can help specifiers and estates teams meet stringent requirements with confidence.

(MoJ approval applies to safer cells up to 1200mm (W) x 960mm (H) x 260mm (D). Larger sizes can be manufactured but require local sign-off.)

1. Engage Early on Risk, Layout and Services

Early coordination between architects, M&E consultants and estates teams reduces redesign later. Walk the route of pipework and electrical services; confirm low-level cut-outs needed; check wall build-ups and fixing zones; and review lines of sight for CCTV. By holding workshops early, teams can identify ligature risks and maintenance requirements before they turn into design problems.

Takeaway: lock down locations, service penetrations and clearances before finalising schedules.

2. Design Out Ligature Risk - Everywhere

Small choices add up. Features that consistently help reduce risk include:

- Sloping top profiles to discourage standing or concealment.

- 10mm radius corners to help reduce injury risk.

- IP3X-compliant grilles designed to limit opportunities for insertion of objects.

- Internal strengthening strut to provide additional resistance against bending and distortion.

- Secure internal fixings concealed from external access.

- Contour Secure cam locks with additional Pin Torx screws on front, side and top to help deter tampering.

Takeaway: anti-ligature is a system of details, not a single component.

3. Specify Materials for the Setting

2mm Zintec or Magnelis steel offers robust performance in custodial spaces, with powder-coated finishes (e.g., PPC RAL 9003 white) widely adopted. In harsher environments or where cleaning regimes are intensive, Magnelis can provide added corrosion resistance. Perimeter sealing (e.g., Arbokol 1025 secure sealant) helps limit prying points and supports hygiene.

Takeaway: match substrate, coating and sealing to the cleaning chemicals, moisture and usage profile on site.

4. Prioritise Cleaning and Planned Maintenance

If cleaning is hard, it won’t happen as often as policy intends. The patented full-height access door on DeepClean Extra+ is designed to make thorough cleaning faster while retaining security when locked. BioCote® anti-microbial protection in the coating can help reduce bacterial growth between cleans.

Takeaway: plan for daily operation as much as for installation; estates teams need fast, safe access.

5. Evidence and Compliance Matter

MoJ approval for safer cells provides specifiers with third-party assurance that the radiator system has been through comparative evaluation and destruction testing under STD/X/SPEC/063. Keep as-built documentation, fixing schedules, and tamper-resistant hardware specs in one place to streamline client sign-off and audits.

Takeaway: build a compliance pack, it saves time at review and handover.

6. Live-environment Installations Need Phasing

Working in occupied custodial areas requires careful phasing, clear isolations and close liaison with operational staff. Modular delivery, pre-drilled fixings, and pre-planned waste logistics help reduce time in sensitive areas and minimise disruption.

Takeaway: plan installation like a clinical operation; the environment demands it.

7. Allow for Local Variations and Sign-off

While safer-cell approval covers specific dimensions, projects often require variations. Where non-standard sizes are needed, align early with stakeholders for local approval and record the rationale within the risk register.

Takeaway: when deviating from the approved envelope, secure local sign-off before manufacture.

8. Don't Forget Aftercare

Provide a simple maintenance guide, torque settings for fixings, and a schedule for inspection. Training custodial staff on safe opening/closing procedures helps keep hardware performing and reduces callouts.

Takeaway: aftercare planning protects performance and whole-life value.

Why DeepClean Extra+ Fits High-risk Settings

DeepClean Extra+ brings these lessons together:

- Anti-ligature geometry and security hardware to help deter tampering

- Heavy-gauge steel construction for day-to-day resilience

- Full-height access for cleaning and servicing

- Anti-microbial coating support to hygiene regimes

- Clear compliance path under STD/X/SPEC/063 for safer cells

For specifiers and estates teams, this means a heating solution designed for the realities of high-risk, high-scrutiny environments.

Designing for High-risk Settings?

Discuss how the MoJ-approved DeepClean Extra+ anti-ligature radiator can support your next prison, custody or detention project, from safer cells to YOIs, 136 suites, custody suites, immigration detention and PRUs.

📞 Call us on 01952 290498

📧 Email sales@contourheating.co.uk

🌐 Find out more about the DeepClean Extra+

-1.png)

/anti-ligature%20vent%20grilles.jpg)